Jaw crusher is a common mining crushing equipment, often used in the fine crushing of ore materials. In the continuous development of the mineral processing industry, the crushing link plays an important role. It not only affects the efficiency of mineral processing and smelting processes, but also directly affects the efficiency of the entire production line. Jaw crusher has the characteristics of high efficiency, energy saving, large crushing ratio, simple structure, convenient maintenance, low operating cost, etc. It stands out among many crushing equipment and becomes the preferred equipment in the crushing industry. Below, New Gaonai Heavy Industry will explain in detail the working principle, composition structure, application field and advantages of jaw crusher.

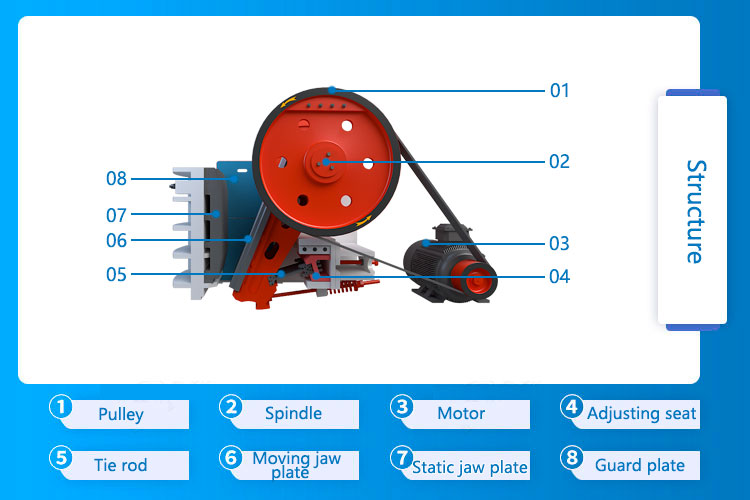

Composition structure and working principle

The jaw crusher is mainly composed of frame, movable jaw plate, fixed jaw plate, eccentric shaft, bearing, pulley, flywheel and other parts. It has a simple structure and a relatively simple working principle. It is mainly through the relative movement between the movable jaw plate and the static jaw plate to squeeze, rub, grind and other actions to achieve the purpose of crushing.

Advantages of jaw crusher

Simple structure: simple structure, few parts, convenient operation and easy maintenance. After simple training, the equipment can be basically operated and maintained.

Smooth operation: The equipment runs smoothly and has a low failure rate. The frame and jaw plate are made of special metal materials, which are strong and durable and can withstand long-term high-load work.

Large crushing ratio: The crushed materials have uniform particle size, and the crushing ratio is generally between 3-6, which can effectively coarsely crush most materials.

Strong adaptability: It can be used to crush hard ore materials, and can also crush building materials with lower hardness.

Energy saving and environmental protection: The energy consumption required for the operation of the equipment is low, and the noise and dust generated also meet environmental protection requirements.

Easy maintenance: The jaw crusher has few parts and is easy to install and replace. The vulnerable parts are made of special metal materials, which are not only hard and durable, but also reduce the equipment failure rate and improve production efficiency.

jaw crusher uses

Mining industry: It can be used to crush ore materials such as iron ore, limestone, copper ore, gold ore, etc., which can not only improve the crushing efficiency, but also reduce the equipment failure rate.

Construction industry: It is commonly used in the processing of materials such as concrete, cement, and glass. In concrete production, the jaw crusher can quickly and efficiently complete the process of sand and gravel crushing and screening.

Chemical industry: Help enterprises complete waste material recycling, material processing and other tasks, thereby reducing the cost of the enterprise and improving production efficiency.

Metallurgical industry: Used to crush the raw materials required for metallurgical furnaces, such as coke, sintered ore, etc., to ensure that the particle size of the charge meets the requirements of the smelting process.

After the above introduction, we know that the jaw crusher is a very popular crushing equipment, which is not only simple in structure but also easy to maintain. We also know the working principle and application field of the jaw crusher, and also understand the advantages of the jaw crusher, so that we can better choose the appropriate crushing equipment. Choosing the right crushing equipment not only improves production efficiency, but also reduces operating costs.

From February 24 to March 31, 2025, Xingaonai will hold a large-scale promotion with the lowest price of the year.

|

|

| PE Series Jaw Crusher | PEV Series European Jaw Crusher |

Author:[Xingaonai]

Comments on “Working principle and application fields of jaw crusher”